- Functional Departments

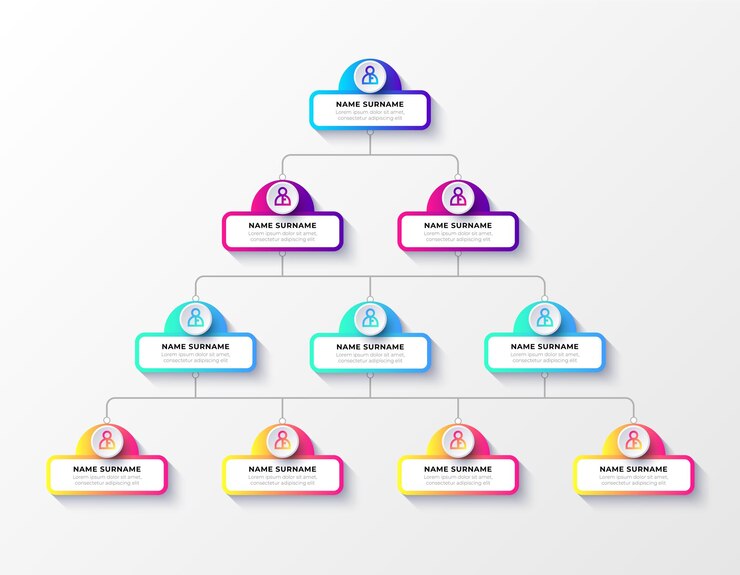

- Hierarchical Structure

- Matrix Organizational Structure

- Communication Channels

- Lean Manufacturing and Flat Organizational Structures

- The Role of Technology in Manufacturing Structures

- Challenges and Considerations in Manufacturing Organizational Structures

- Employee Training and Skill Development

- Sustainability Integration

- Global Supply Chain Considerations

- Regulatory Compliance and Risk Management for Optimal Output

- The Evolving Role of Leadership

- Conclusion

Functional Departments

Production Department

Quality Control Department

Ensuring the quality of manufactured products is paramount. The quality control department is responsible for implementing and monitoring quality assurance processes. This department often works closely with the production team to identify and rectify any issues that may compromise the quality of the final product.

Research and Development

Innovation is a key driver of success in the manufacturing industry, and achieving optimal output requires a well-defined manufacturing organizational structure. A dedicated research and development (R&D) department is crucial for staying ahead of the competition. This department, integral to the manufacturing organizational structure, focuses on exploring new technologies, improving existing products, and finding ways to enhance overall manufacturing processes, ensuring optimal output at every stage.

Hierarchical Structure

Top Management

At the top of the hierarchy are executives and top-level managers responsible for making high-level strategic decisions. This includes setting long-term goals, establishing company policies, and ensuring the overall success of the organization.

Middle Management

Middle managers play a pivotal role in the dynamic landscape of a Manufacturing Organizational Structure, acting as the linchpin between top management and front-line employees. Tasked with implementing strategies set by upper management, they bear the crucial responsibility of overseeing day-to-day operations. In departments like production, quality control, and R&D, specialized middle managers navigate the intricacies of the Manufacturing Organizational Structure, ensuring seamless coordination and effective execution of organizational goals. Their strategic positioning facilitates a streamlined flow of communication and operations, enhancing the overall efficiency of the manufacturing process.

Front-Line Employees

Front-line employees are the backbone of manufacturing. This includes machine operators, assembly line workers, and other roles directly involved in the production process. Clear communication channels between front-line employees and middle management are essential for a seamless workflow.

Matrix Organizational Structure

In some manufacturing organizations, a matrix structure is adopted to combine the benefits of functional and hierarchical structures, ensuring optimal output. This approach allows for more flexibility and improved communication across different departments, leading to enhanced efficiency and productivity.

Project Teams

Matrix structures often involve the formation of project teams, bringing together individuals from different departments to work on specific projects. This cross-functional collaboration fosters innovation and ensures that the expertise of various departments is utilized efficiently.

Dual Reporting

Matrix structures involve dual reporting, where employees report to both a functional manager (such as a department head) and a project manager. This dual reporting system is designed to ensure optimal output by balancing the demands of both functional and project-related responsibilities.

Communication Channels

Effective communication is the lifeblood of any organization. In manufacturing, where precision and timing are crucial, having clear communication channels is paramount.

Vertical Communication

Vertical communication flows up and down the hierarchical structure, ensuring optimal output throughout the organization. Top-down communication ensures that strategic goals and decisions are effectively conveyed to all levels of the organization. Meanwhile, bottom-up communication allows front-line employees to provide valuable feedback and insights, contributing to optimal output.

Horizontal Communication

Horizontal communication occurs between individuals and departments at the same hierarchical level. This is particularly important in matrix structures where collaboration between different functional areas is essential. Regular meetings, project updates, and a collaborative culture facilitate smooth horizontal communication.

Lean Manufacturing and Flat Organizational Structures

In recent years, the manufacturing industry has witnessed a paradigm shift towards lean manufacturing principles, all aimed at achieving optimal output. Lean manufacturing focuses on maximizing efficiency by eliminating waste and optimizing processes. To complement these principles and ensure optimal output, many organizations are adopting flat organizational structures.

Lean Manufacturing Principles

Waste Reduction

Lean manufacturing emphasizes the identification and elimination of various forms of waste, including overproduction, defects, and unnecessary inventory. By focusing on these areas, companies can significantly reduce costs and improve overall efficiency. A manufacturing organizational structure aligned with lean principles streamlines processes, fosters better communication, and enhances workflow, ultimately reducing the likelihood of inefficiencies and resource wastage. This alignment not only ensures that every step of the production process adds value but also enables quicker response times to market demands and customer needs. Adopting this approach helps organizations remain competitive and responsive in a fast-paced industry.

Continuous improvement is a cornerstone of lean manufacturing, driving the ongoing refinement of processes to achieve greater efficiency and effectiveness. An organizational structure that fosters a culture of continuous improvement empowers employees at all levels to actively participate in this journey. By encouraging open communication and feedback, organizations enable their workforce to contribute innovative ideas for enhancing processes, reducing waste, and improving overall productivity. Cross-functional collaboration becomes particularly essential in this context, as valuable insights and ideas may emerge from various departments, including those not traditionally involved in process optimization. This holistic approach ensures that every aspect of the operation is continually evolving towards greater efficiency and success.

Flat Organizational Structures

Traditionally, manufacturing organizations followed a hierarchical structure with multiple layers of management. However, a shift towards flat organizational structures has gained momentum.

Decentralized Decision-Making

Flat structures reduce the number of hierarchical levels, promoting decentralized decision-making, which empowers employees at all levels to take initiative and make decisions without waiting for approvals from multiple layers of management. This approach can lead to faster response times, as decision-makers are closer to the front lines and can address issues more promptly. In manufacturing, where quick decision-making is often critical to maintaining production schedules and responding to unforeseen challenges, a flat structure can significantly enhance agility. By streamlining communication and reducing bureaucratic delays, flat structures also foster a more collaborative and innovative work environment, further driving efficiency and productivity.

Employee Empowerment

Empowering employees to make decisions and take ownership of their work is a central tenet of flat organizational structures. In manufacturing, this can translate to increased responsibility for front-line employees, encouraging them to contribute to process improvements and problem-solving.

The Role of Technology in Manufacturing Structures

As the manufacturing landscape evolves, technology continues to play a pivotal role in shaping organizational structures. The integration of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and automation has a profound impact on how manufacturing organizations are structured.

Digital Transformation

Flat structures reduce the number of hierarchical levels, promoting decentralized decision-making and empowering employees at all levels to take ownership of their work. This shift enables faster decision-making, greater innovation, and increased agility in responding to market changes. Manufacturers are increasingly embracing digital transformation to enhance efficiency and competitiveness, recognizing the importance of integrating advanced technologies into their operations.

This may involve the implementation of smart manufacturing systems that rely on real-time data, analytics, and automation to streamline processes and reduce waste. As a result, organizational structures need to incorporate roles and departments focused on managing and optimizing these digital systems, ensuring that the company can fully leverage the benefits of digital transformation while maintaining flexibility and responsiveness in a rapidly evolving industry.

Cross-Functional IT Teams

With the rise of technology in manufacturing, the IT department has become an increasingly critical component, playing a pivotal role in driving innovation and efficiency. Cross-functional IT teams that collaborate closely with production, R&D, quality control, and other key departments are essential for the smooth operation of modern manufacturing processes. This collaboration ensures that technology is seamlessly integrated into all facets of the organization, from the shop floor to the executive suite. By fostering strong communication and collaboration across departments, these IT teams help to create a more cohesive and connected manufacturing ecosystem, leading to improved productivity, reduced downtime, and a stronger competitive edge in the marketplace.

Challenges and Considerations in Manufacturing Organizational Structures

While designing an optimal manufacturing organizational structure, it’s essential to recognize potential challenges and factors that can impact its effectiveness.

Resistance to Change

Implementing a new organizational structure often faces resistance from employees accustomed to existing workflows. Effective change management strategies are crucial to address concerns, communicate the benefits, and ensure a smooth transition.

Scalability

As manufacturing firms grow, scalability becomes a critical consideration. The chosen organizational structure should allow for seamless scalability, accommodating increased production volumes and expanding teams without sacrificing efficiency.

External Factors

Manufacturers are influenced by external factors such as market trends, economic conditions, and regulatory changes. The organizational structure must be adaptable to navigate these external forces and position the company for sustained success.

Employee Training and Skill Development

One often underestimated but critical aspect of an effective manufacturing organizational structure is investing in employee training and skill development programs. In the fast-paced world of manufacturing, keeping the workforce updated on the latest technologies, industry best practices, and safety protocols is essential.

Ongoing Training Programs

Implementing ongoing training programs ensures that employees remain adept at using new technologies and equipment, keeping their skills relevant and up-to-date. This is particularly crucial in an era where technological advancements in manufacturing are rapid and constantly evolving. By regularly updating employees’ knowledge and capabilities, organizations can minimize the risk of skill gaps and operational inefficiencies. A skilled workforce not only contributes to enhanced productivity but also fosters a culture of continuous improvement and innovation, where employees are motivated to seek out better ways to perform their tasks, driving overall business success and maintaining a competitive edge in the market.

Cross-Training Initiatives

Cross-training employees across different roles within the organization can be beneficial. This not only makes the workforce more versatile but also helps in addressing skill gaps during peak production periods or unexpected shortages in specific areas. Cross-functional knowledge also fosters better collaboration between departments.

Sustainability Integration

In the modern manufacturing landscape, sustainability has become a key consideration for companies aiming to stay ahead in a competitive market. Integrating sustainable practices into the organizational structure is not just a matter of meeting regulatory requirements; it’s also about responding to consumer demand for environmentally responsible products. Companies that prioritize sustainability can reduce operational costs through energy efficiency, waste reduction, and resource management. Moreover, embracing sustainability enhances brand reputation and attracts eco-conscious customers and investors. It is increasingly seen as a strategic competitive advantage that drives long-term growth and resilience in an ever-evolving industry.

Environmental Management Departments

Establishing dedicated departments or teams focused on environmental management and sustainability initiatives is becoming more common. These teams work to ensure compliance with environmental regulations, reduce the environmental impact of manufacturing processes, and explore eco-friendly alternatives.

Sustainable Supply Chain Integration

A sustainable manufacturing organizational structure extends beyond the factory walls to the entire supply chain. Collaboration with suppliers who adhere to sustainable practices and integrating environmentally friendly materials into production processes contributes to a more eco-conscious manufacturing ecosystem.

Global Supply Chain Considerations

For manufacturing organizations with a global footprint, the structure must account for the complexities of managing a diverse and geographically dispersed supply chain.

Regionalized Operations

Organizing manufacturing operations regionally can help in tailoring production to meet specific market demands, reducing lead times, and minimizing transportation costs, all of which contribute to achieving optimal output. By having manufacturing facilities closer to key markets, companies can respond more swiftly to customer needs and market fluctuations, ensuring that production processes are aligned with demand.

This proximity allows for better inventory management, quicker turnaround times, and the ability to implement region-specific innovations, all of which are essential for maintaining optimal output. Additionally, regional teams can be empowered to make decisions that align with local market conditions, enabling them to adapt strategies, production schedules, and resource allocation in real-time. This localized approach fosters greater agility, enhances customer satisfaction, and ultimately drives competitive advantage in the global marketplace.

Centralized Coordination

While regionalized operations offer significant advantages, such as catering to local market needs and enhancing customer relations, centralizing certain key functions can greatly enhance overall business performance. Strategic decision-making, technology infrastructure, and overarching policies are examples of functions that, when centralized, ensure a consistent and cohesive approach across all locations. By having a unified strategy, businesses can maintain brand consistency, streamline processes, and eliminate redundancies. This centralized coordination not only fosters a strong, unified brand identity but also ensures operational efficiency by aligning all regional activities with the company’s core objectives, ultimately leading to more effective and scalable growth.

Regulatory Compliance and Risk Management for Optimal Output

Manufacturing is subject to a myriad of regulations and potential risks. To achieve optimal output, an effective organizational structure should include mechanisms for ensuring regulatory compliance and managing risks proactively.

Compliance Officers and Teams

Appointing compliance officers or teams responsible for staying abreast of regulatory changes and ensuring adherence is crucial. This is especially true in industries with stringent regulations, such as pharmaceuticals or aerospace manufacturing.

Risk Assessment and Mitigation Strategies

Integrated risk management teams should be part of the organizational structure to identify potential risks, assess their impact, and develop mitigation strategies. This proactive approach helps in minimizing disruptions to production and maintaining a resilient manufacturing process.

The Evolving Role of Leadership

In the rapidly changing manufacturing landscape, leadership roles within the organizational structure are evolving to meet new challenges and opportunities.

Adaptive Leadership

Leaders must be adaptive and open to change. The ability to navigate uncertainties, embrace innovation, and lead teams through transformations is crucial. This requires a leadership structure that fosters agility, encourages feedback, and supports continuous learning.

Digital Leadership

As technology becomes more integral to manufacturing, leaders need to possess digital literacy and an understanding of how technology impacts various aspects of the business. Digital leadership involves leveraging technology for strategic decision-making, process optimization, and fostering a culture of innovation.

Conclusion

In conclusion, designing an optimal manufacturing organizational structure is a multifaceted endeavor that goes beyond traditional hierarchies. It involves embracing technological advancements, prioritizing sustainability, adapting to global complexities, ensuring regulatory compliance, and nurturing a skilled and empowered workforce.

The manufacturing landscape will continue to evolve, presenting new challenges and opportunities. Organizations that proactively adjust their structures, cultivate a culture of continuous improvement, and invest in their most valuable asset – their people – will be well-positioned for sustained success in the dynamic and competitive world of manufacturing. The journey towards an optimal organizational structure is a continuous one, requiring a commitment to adaptability, innovation, and excellence.

Thank you for taking the time to read our blog! We hope you found it informative and engaging. Don’t miss out on more valuable insights – be sure to explore our other blog, “Strategies for Efficient Workforce Management in Manufacturing.” Your journey to enhanced knowledge and efficient practices awaits!